People in our community are searching for ways to help amid the COVID-19 outbreak. This outbreak has sparked creativity and innovation in many searching for solutions and ideas to help front line workers. A local Carrollton citizen, Cole Ayers, saw an opportunity to leverage technology to assist Tanner Health System in creating face shields for hospital employees.

After reviewing several articles of inventor spaces and university labs around the country utilizing their technology to assist with similar projects, Ayers reached out to Tanner Health System in Carrollton to discover a large-scale project underway. Tanner had just placed an order for materials to create face shields for front-line hospital workers. In that order were sheets of plastic and a 72-foot roll of foam that volunteers were painstakingly cutting by hand to make face shields. Volunteers had cranked out 150 face shields, but the process was slow, and the need by hospital staff was great.

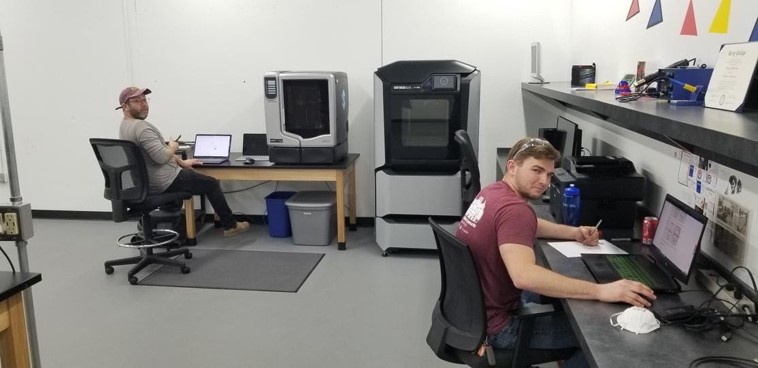

After hearing this news, Cole Ayers decided to reach out to our local maker space to tackle this project. The Tinker’s Box, a partnership between the University of West Georgia and Carroll Tomorrow, is a maker space located in Carrollton for local inventors, students, and entrepreneurs to create and prototype their ideas. Witt Teem, manager of the Tinker’s Box, quickly agreed to assist with this project and opened up The Tinker’s Box for use. This space allowed Ayers to draft a template on a laser for cutting the plastic sheets with a band saw.

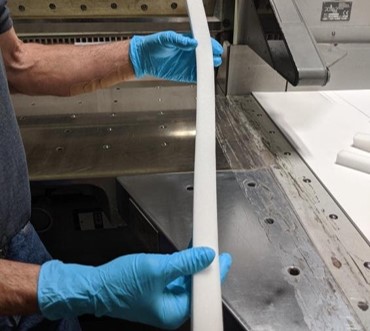

The foam used to line the mask would prove to be the next hurdle for the time sensitive project. After several trial and error tests, Ayers was on the hunt for something that would not leave residue on the foam as it would come in direct contact with healthcare employees’ faces. Greg Smith, with Printed Specialties in Carrollton, stepped up to the plate and offered to cut the foam using machinery in their facility to be ready for pick up and assembly. After coordination with The Tinker’s Box, Printed Specialties, and Tanner Health System, the project was ready for assembly. The Tanner Foundation enlisted the help of several Magnolia Ball volunteers: the group assembled 800 face shields in one day and the remaining count the following day. This collaborative project is an excellent example of our community at its finest, working together to fill a need during this unprecedented time.